Sustainability at HPL

We’re committed to making furniture that’s healthy—for our clients and for the planet. To do this, we take the aerial view and strategize ways to reduce impact across each product’s lifecycle. Then we go granular with solutions.

We prioritize local, eco-friendly materials, invest in energy-efficient manufacturing based in California, and reduce waste at every step. We also build our furniture to last. For example, we recently refurbished dozens of conference tables that we made over a decade ago. This means less waste for the planet and more savings for our clients.

And we continue to research and update our sustainable practices, staying true to the values we share with our clients: doing our very best to take care of our world.

We shop local

We source materials locally. As a California-based operation, we’ve built close relationships with in-state and West Coast suppliers. Nearly all of our go-to vendors are within an hour drive. This means less fuel spent on transporting materials and less cost to the planet we all share.

We mind our materials

Healthy products start with good-for-you materials. So, we look for ingredients that work hard at going easy on the ecosystem. For example, we use UV-cured finishes because they’re low on harmful VOC emissions, require fewer coats so we use less, and resist wear and chemicals for longer-lasting furniture. And underneath that finish: recycled core substrates, water-based adhesives, and NAF (no added formaldehyde) wood. From top to bottom, we’re building sustainability into our furniture.

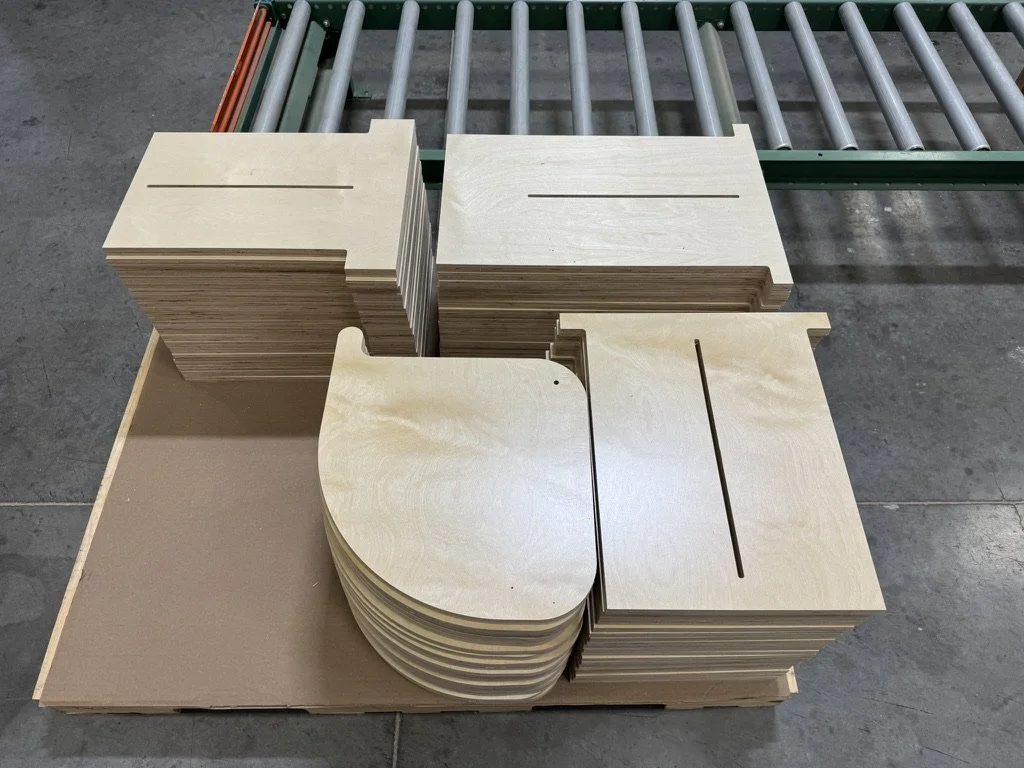

We go big on less waste

It’s a no brainer: Less stuff in landfills means less pollution. So, we look to minimize waste at every step. We leverage advanced software to use the most of every piece of material. Leftover bits that can’t be composted are ground and compressed to reduce the landfill load. To nix packaging, we ship products blanket-wrapped. At cleanup, we use thinner extracted from leftover stains to scrub our equipment. Then, we run reports, improve, and repeat.

We’re thrifty with energy

We use only the energy we need to get the job done. It’s common sense, and it reduces our carbon footprint. Our motors, compressors, and other equipment are calibrated to use just the right amount of power, and they run on an as-needed basis. When the job is complete, the system is at rest. We believe in working hard but efficiently.

“We believe in creating products that last, with minimal environmental impact. This starts with selecting low-VOC materials from local suppliers. Then, at our California factory, we carefully optimize every piece to reduce waste, ensuring each product is crafted with care and purpose.”

— Frank Stratiotis, President, HPL Contract

Targets

2025

FSC Certification

2025

Indoor Air Quality/ Indoor Air Advantage Gold for all our focus tables and lockers

Certifications

VOC Emission Test Certificate for all our standard conference tables

As a California-based manufacturer we adhere to all CARB requirements for procurement and manufacturing