West Coast Built.

There’s a reason they say, West Coast Best Coast. We're from California—and we're proud of it. Every piece of furniture we build is designed, engineered, and manufactured right here in Patterson, CA.

From our original factory to our new 130,000 sq. ft. facility under construction just down the road, our commitment to American manufacturing is at the core of who we are.

We don’t just make furniture—we build it better, faster, and stronger.

California-built. Performance-driven. Always American-made.

Our Process, From Start to Finish.

See how innovation and precision come together inside our state-of-the-art facility. This full video takes you behind the scenes of our end-to-end manufacturing process.

Our team

We’re a people-centric company. We want our employees to thrive along with our clients. So, we train them thoroughly in our engineering-driven methods of crafting furniture. Many of our engineers worked their way up from the floor, and their know-how circles back to inform training for the on-the-ground teams.

We’re proud that most of the HPL team have been with the company for a decade or more. The collective expertise at HPL ensures the quality, innovation, and capacity that we promise to our clients. And that’s gratifying for us all.

Our equipment

Machinery is a fixation at HPL. We invest more in equipment than any of our competitors. These investments give us the edge on quality, speed, and scale. We can meet demand and deadlines, while still producing beautiful, durable office furniture.

Winstore

-

We work on a big scale—both in size and volume—so we rely on the Windstore to move and stash large parts, expediting our process. No need for cumbersome racks or forklifts.

Selco Saw

-

Always looking to match precision with speed, we turn to the Selco Saw, which can cleanly cut through a stack of four panels at once, getting the job done four times faster.

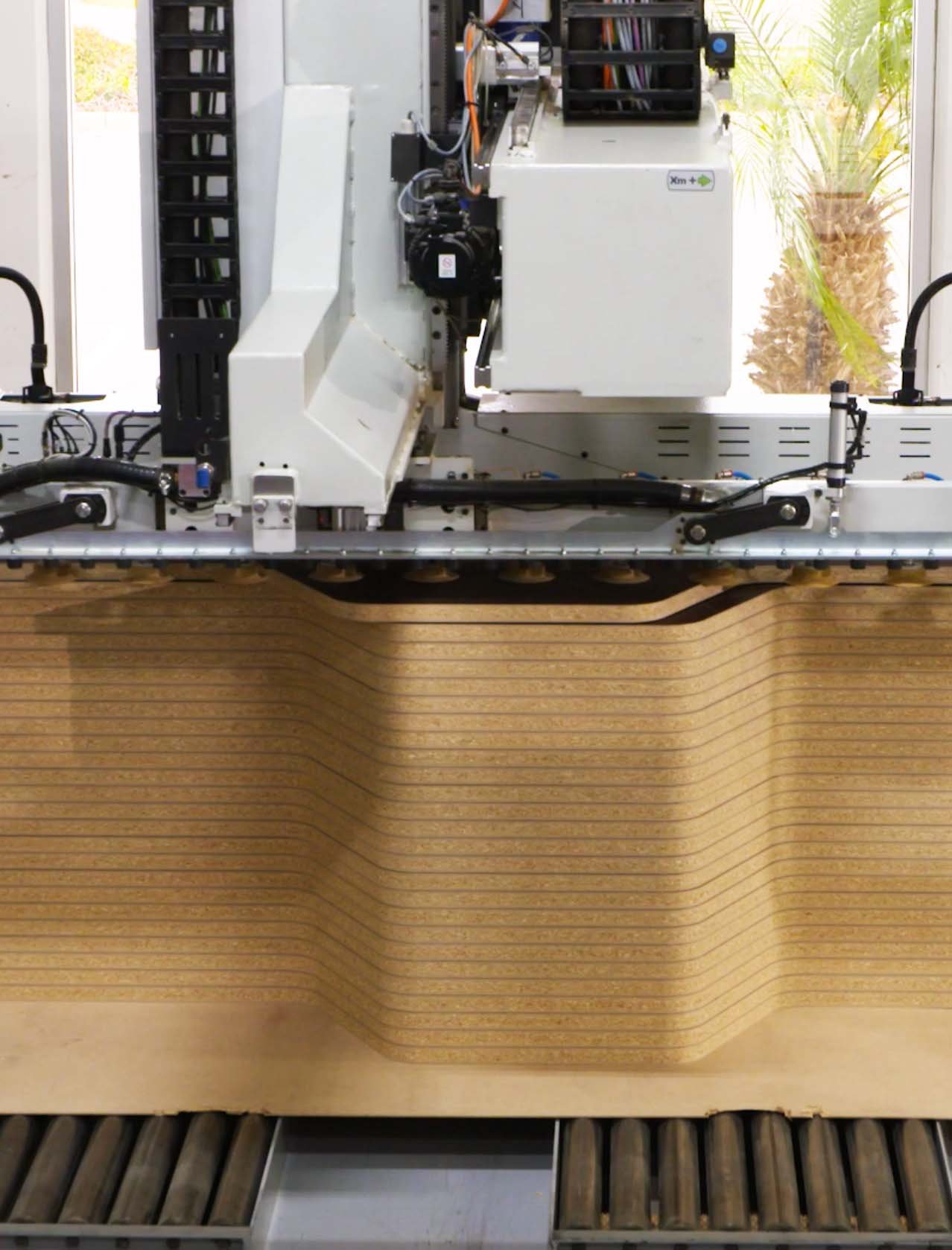

Rover B CNC

-

As part of our sustainable practices, we use the Rover B to help us use as much of our materials as possible. It also integrates easily with the Windstore and our labeler, keeping everything organized.

Homag Edge Bander

-

We bring our commitment to quality to every seam: instead of edge-banding elements like locker doors with messy glue, we use this Homag edgebander and a hot-air process to seal a polished look.

BSC Brema

-

The Brema drilling machine is a favorite of Frank Stratiotis, HPL’s President. Why? Efficiency. It can drill on both sides at once, streamlining the process.

Gannomat

-

Accuracy is key to fitting each part perfectly. That’s the superpower of the Gannomat, which snaps hinges and hinge-plates into place, so install is a cakewalk. A rare machine in the industry, and we actually have two!

ABD

-

To ensure a sturdy construction, we use an ABD machine, which horizontally drills and inserts dowels to secure a strong hold. This tool’s deftness and speed is essential to delivering a clean look at scale and on deadline.

Case Clamp

-

To create quality on repeat, lining up every edge just so is crucial. The Case Clamp helps us lock in the right angles, letting the glue adhere for a tight, durable construction.

Rover Edge

-

Because every detail needs to be perfect, we invested in the Rover Edge—a machine few of our competitors have. It gives us the unique ability to apply seamless edge-banding along curves or unusual angles for a clean, sleek look.

Case Studies

Investments in our team and equipment allow us to achieve extraordinary results. Marshalling our engineering brain trust, factory floor experts, and advanced automation, we’ve developed innovative products for huge projects and long-term partnerships with the world’s biggest companies.

Custom lockers for a vast headquarters

To solve storage needs for an online retailer’s new headquarters, we developed a locker system for 14,000 workers. Sporting a built-in millwork look, we equipped these cubbies with charging capacity, advanced locking technology, and a varied palette matched to the design vision. These lockers are packed with value.

Tech-friendly furniture tailor-made for a streaming empire

A major streaming service tapped HPL to create furniture with tech-friendly features and a custom look. Our solution: conference tables and credenzas built with tucked-away compartments for power, data and video jacks. To amplify their versatility, we outfitted these overachievers in varied sizes and finishes.